If you have ever burned your toast or cooked a cake beyond all recognition, you have already glimpsed firsthand the basic function of a carbonization machine. But, you may be wondering how this device can be used for anything worthwhile – let alone profitable.

The following article will provide a comprehensive overview to better understand the function of the carbonization machine and how it can be applied to answering a variety of current needs while turning a profit.

Carbonization and the Production of Charcoal

Long before the advent of gas companies and the awesome power of nuclear energy, mankind was making charcoal. Charcoal is a naturally occurring compound that is produced prolifically in nature. Early humans at the dawn of the agricultural era were quick to learn how to produce charcoal and it was used in a large variety of purposes.

Charcoal is a primary source of fuel for cooking, warmth and a variety of other household purposes. This type of fuel is still used in vast quantities in all stages of a country’s development. Charcoal is also an important soil amendment and has extensive application in the fields of agriculture and gardening. Click here to know more: https://bestonpyrolysisplant.com/.

This was a well-known fact to early farmers looking for ways to make their crops a little healthier. Archaeological studies have shown that our ancestors utilized a rudimentary form of the carbonization machine to produce the carbon they would use for a variety of purposes.

The magic of pyrolysis was achieved in the simplest ways. A simple hole dug in the earth would serve as a suitable oven in which to control the amount of oxygen feeding a slow burning fire below – much like your cake carbonizing in the oven.

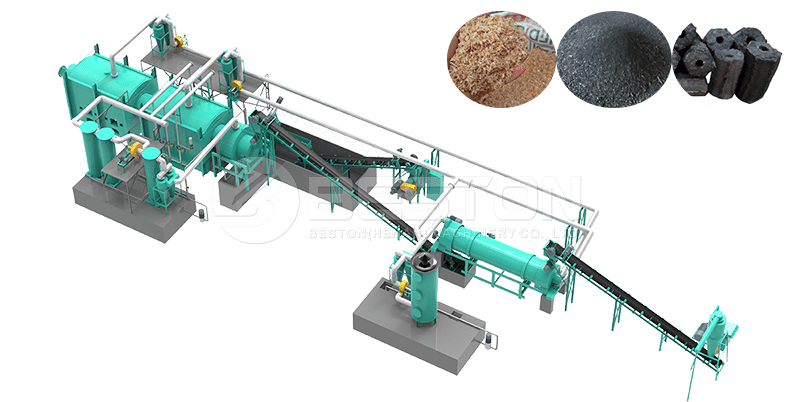

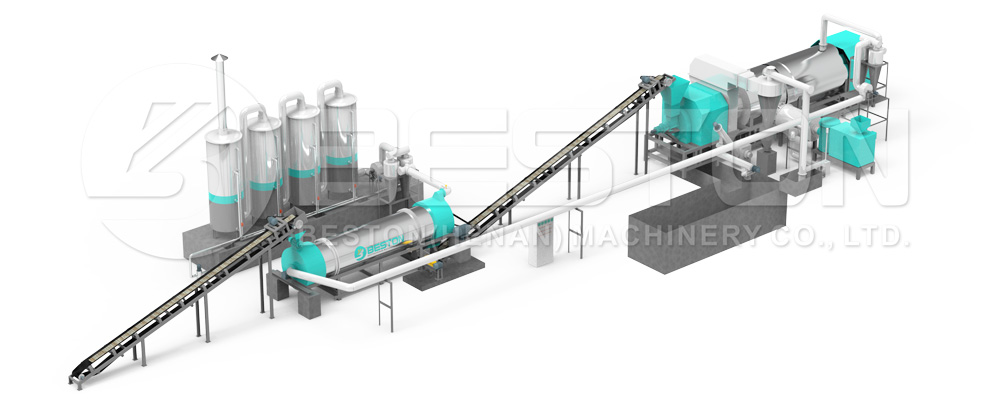

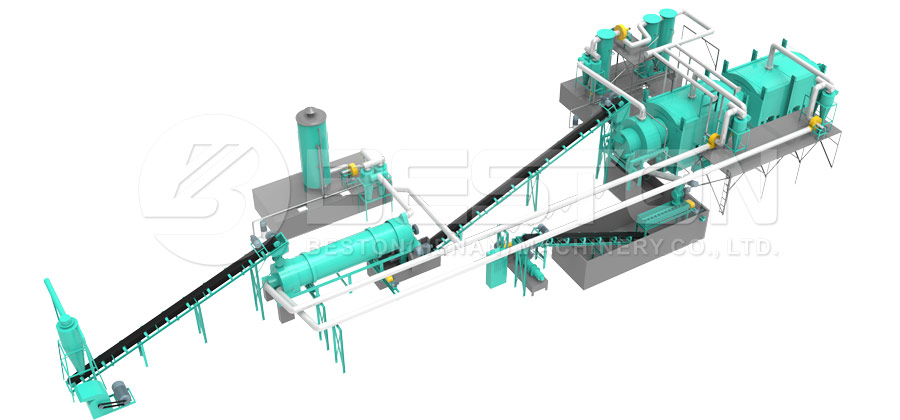

Today’s highly advanced coconut shell charcoal making machine can be applied to turning biological wastes from a wide variety of industries to create a product that is just as needed in society as it has ever been.

Why Invest in Modern Carbonizations Machines

Today carbon is used in both outdoor and indoor cooking, in the preparation of agricultural land for crops and harvest, high-tech filtrations systems and an endless list of other purposes. To meet the demand today antiquated methods of transforming biomass into profitable carbon are obsolete. Actually, anything but a first-rate carbonization machine for this purpose represents an environmentally-hazardous way of obtaining a very important need.

Carbonization serves two vital purposes today and it is the efficacy of the process that ensures these needs are met without causing further damage to the environment. First, there is an endless stream of waste produced by our super modern cities and industries and carbonization is the answer.

Top-quality carbon can be created from wood fibers produced by construction and furniture manufacturers. Human and animal waste can also be used in this way, making carbonization an important process in dealing with the rising floods of waste produced by our societies.

The second reason, and the most important to an enterprising mind like yourself, is the profitability of the process. Carbon is a ubiquitous need in all aspects of human life. Charcoal (https://bestonpyrolysisplant.com/charcoal-making-machine/) provides for humanity at the most basic level as it supports the weight of a hungry population by serving the agricultural industry. Carbon also serves innumerable other purposes and is always in demand.

With a literally infinite supply of source materials and an endless need, carbonization is the industry of tomorrow and modern carbonization machines are the tool needed to rake in a profit.