Some of the very best producers of coconut shell charcoal making machinery export their biochar production equipment to the global market space. They have customers from dozens of different parts of the world, including Europe, Australia, South Africa, and the Philippines. The main benefits of top of the range coconut shell biochar machine is innovate design implementations, first-class manufacturing processes, reliable performance, high-quality components, competitive price tags, and expedited international shipping options.

When it comes to the working process, a typical biochar machine employs oxygen-free carbonization technology and extremely high temperatures to transform biomass waste into biochar and biogas. Both biogas and biogas are valuable commodities, as they are useful raw material resources for many different industries. Coconut shell charcoal, for example, is perfect for use as a BBQ fuel as it has a clean burn (no smoke) and high kilocalorie content.

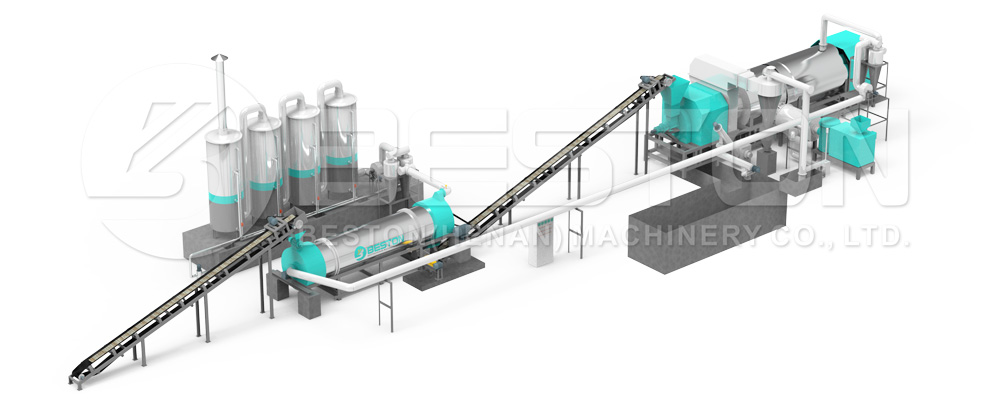

One of the most talked-about manufacturers in the charcoal making machine sector happens to be Beston. The manufacturer deploys some of the most advanced engineering technology in its biochar production machinery. A few months ago the manufacturer shipped one of its machines to a waste processing facility in the Netherlanderlands. Click here to know more about Beston Group.

The good thing about biochar making machines is that as well as processing coconut shell waste, they also convert other types of biomass waste, such as bamboo, palm kernels, olive shells, peanut shells, sawdust, and straw, into bio charcoal. To learn more about the types of biomass waste that Beston’s machines can process, visit the manufacturer’s official website.

Some important specs to take note of for different coconut shell charcoal making machines include working method, hourly feeding capacity, reactor size, total power, reactor pattern, floor area requirements, cooling method, operating pressure, heating materials, and service life. The majority of sawdust charcoal machine can convert a large variety of biomass-based raw materials into bio gas and bio char.

The average working life of a biochar machine is seven years. After that time period, the main reactor chamber generally needs to be replaced for safety reasons. When carbonization requires temperatures exceeding 500 degrees Celcius, it’s not hard to understand why some parts have a limited life span. The good news is that it is very easy to make a very healthy return on investment during the life span of a typical coconut shell charcoal making machines providing you have cheap access to raw materials in your country.