Pyrolysis plants are in high demand. With the right equipment, you can convert rubber waste, like old tires, into usable materials like oil. These materials can then be sold for a profit. With that said, equipment like this is going to require a fairly large investment up front. These tips will help you to accurately compare costs.

Look At Operating Costs

It’s easy to overlook the cost of utilities. It takes quite a bit of power to convert a material like rubber into sellable oil. Because of this, the operating cost of pyrolysis plant can be very high.

If you want to reduce your pant cost, the smartest thing you can do is invest in a machine that is energy-efficient. If you try to calculate the cost of utilities ahead of time, you won’t be caught off guard by this expensive and will be able to invest in a plant that you can operate without any issue.

Comparing The Cost Of Different Plants

The cost of a plant will vary wildly based on a number of factors, such as the manufacturer that made the plant, the type of plant you choose, and where you buy that plant from. Instead of rushing to make a purchase, it’s best to compare numerous plants so that you can see where the best deals are.

If you look at different options, you’ll quickly see that some plants are more affordable than others. With that said, you won’t want to assume that the plants with the lowest price tag are offering the best deal. You’ll want to examine these plants closely to see what you’re getting for your money.

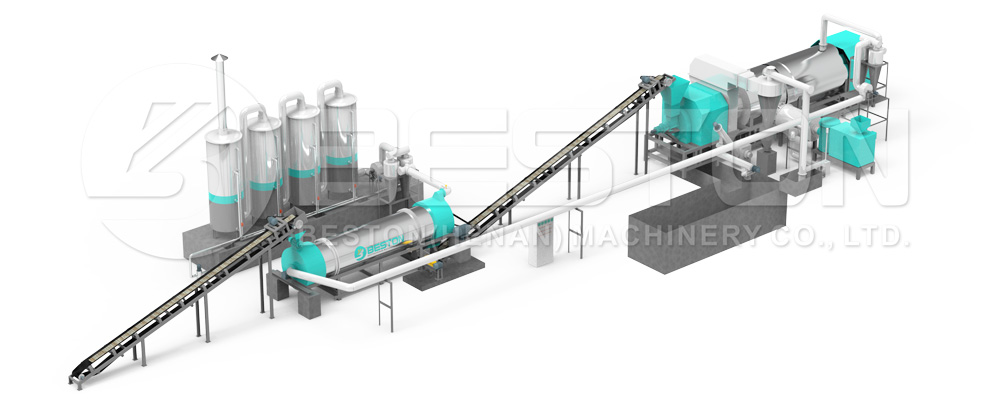

Buying A Production Line

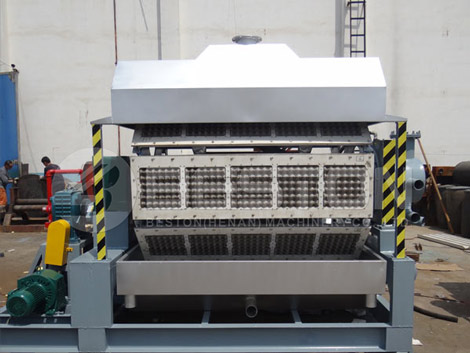

If you’re going to be investing in multiple pieces of equipment, you may not want to purchase this equipment separately. Instead, it’s likely that you’ll want to invest in a production line.

If you do buy a production line, you’ll be able to get everything you need from one place. You’ll also receive a discount on the machinery that you do buy. This will leave you with exactly what you need for your waste tyre pyrolysis machine, and you’ll spend less in total.

Other Costs To Consider

There are several other costs you’ll want to think about when purchasing a pyrolysis plant. In addition to the cost of utilities, you’ll want to look at the cost of storing the oil that you produce. Will you have to invest in additional equipment for storage?

You should also think about what you’ll be paying for shipping. International vendors often have excellent prices on pyrolysis machinery. However, you may have to spend more in order to have your equipment shipped to you from another country. Make sure you’re not surprised by the total cost of shipping.

If you follow this advice when comparing waste tire pyrolysis plant costs, you’ll be able to spend less while still purchasing the equipment that you need. Don’t let rubber tires go to waste! Convert them into something usable that you can sell for a major profit.