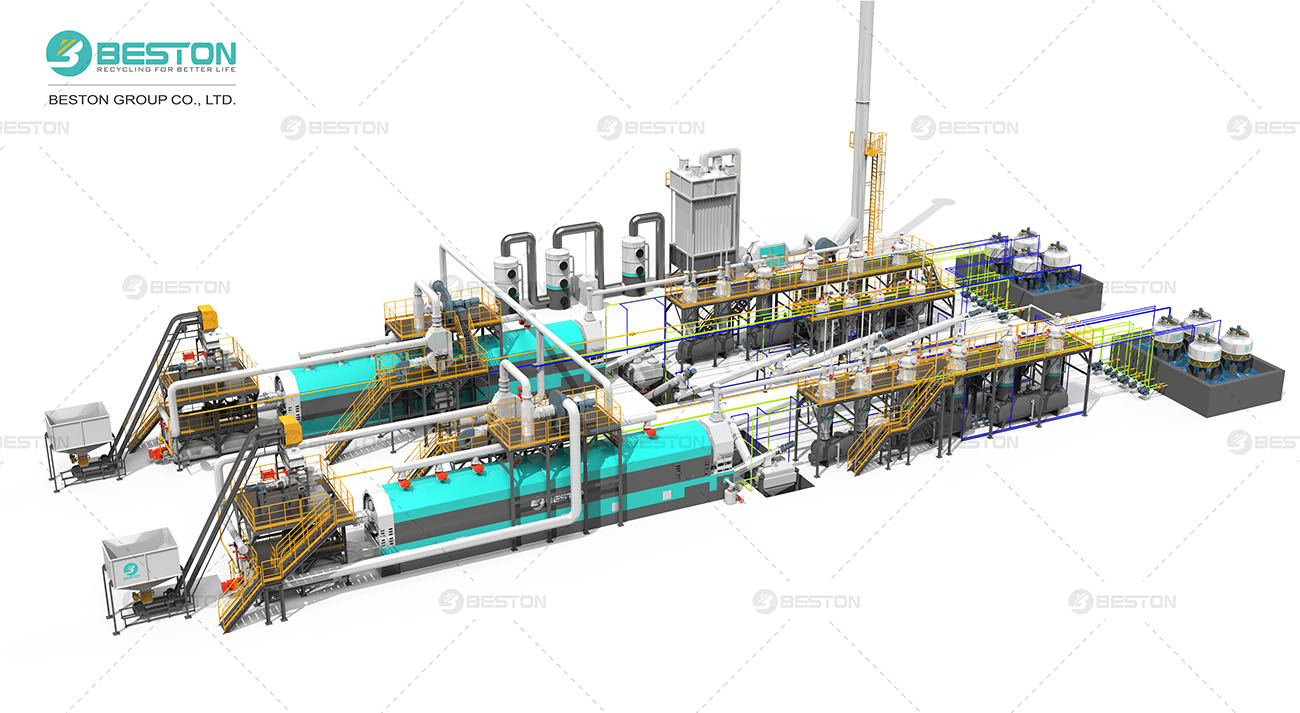

Landfills have long been considered a necessary evil, the final resting place for our discarded waste. However, with environmental concerns escalating and a growing awareness of the finite nature of our resources, innovative solutions are essential. Pyrolysis, a cutting-edge technology, has emerged as a promising avenue for transforming landfill waste into valuable resources. In this in-depth exploration, we’ll delve into the world of Beston pyrolysis plant and how they are revolutionizing the way we manage and repurpose landfill waste.

Understanding Pyrolysis:

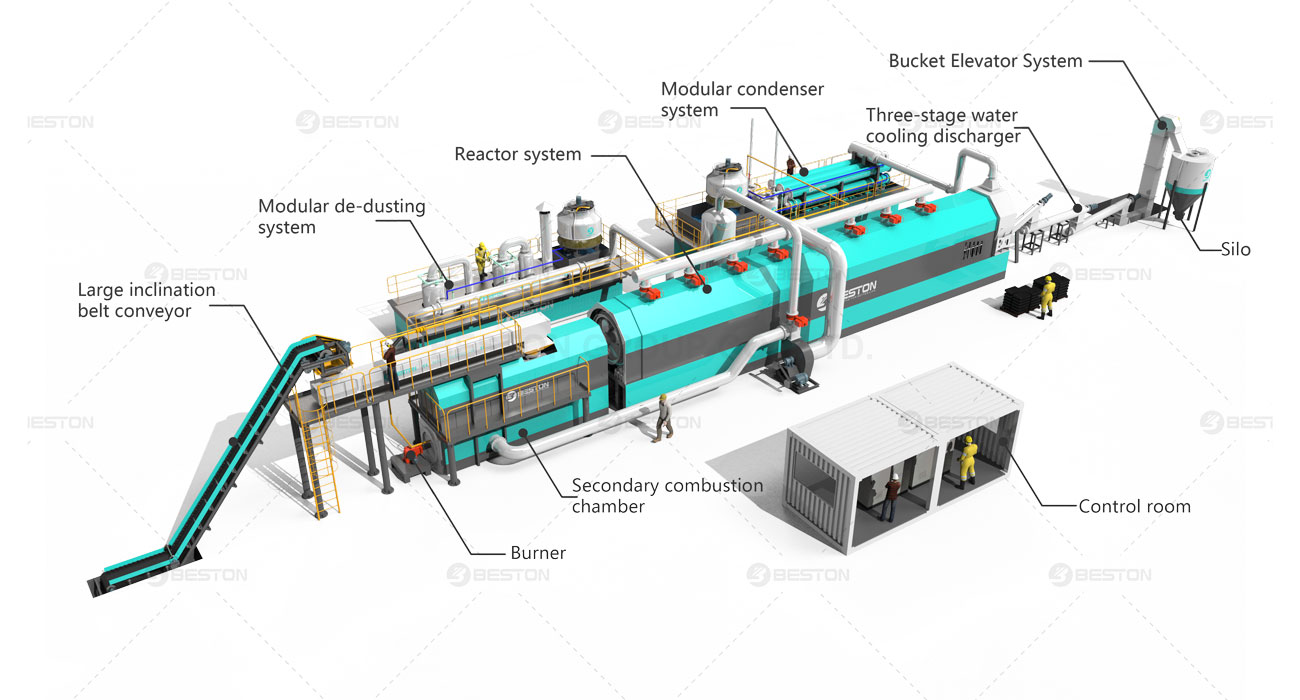

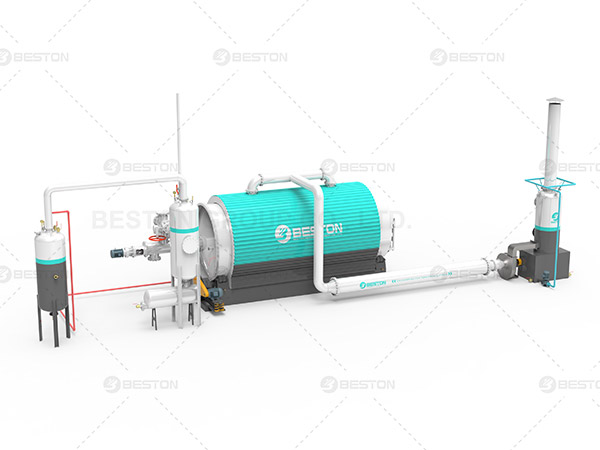

Pyrolysis is a thermal decomposition process that involves breaking down organic materials at elevated temperatures in the absence of oxygen. This unique process leads to the creation of valuable by-products such as biochar, bio-oil, and syngas. Unlike traditional incineration methods, pyrolysis operates in an oxygen-deprived environment, minimizing harmful emissions and maximizing resource recovery.

The Environmental Imperative:

Landfills contribute significantly to environmental degradation, emitting greenhouse gases and leaching harmful substances into soil and water. Pyrolysis presents a compelling solution by addressing these issues at their root. Through controlled thermal decomposition, the process mitigates the release of harmful pollutants, providing an eco-friendly alternative for managing landfill waste.

Types of Pyrolysis Innovations:

Slow Pyrolysis:

Slow pyrolysis involves heating organic materials at relatively low temperatures (300-500°C) over an extended period. This method prioritizes biochar production, a stable carbon-rich material with applications in agriculture and carbon sequestration. Slow pyrolysis is particularly effective in converting woody and fibrous materials found in landfill waste. View the continuous pyrolysis plant design.

Fast Pyrolysis:

Fast pyrolysis operates at higher temperatures (500-800°C) with shorter residence times. This rapid process is ideal for maximizing the production of bio-oil, a versatile liquid that can be further refined into biofuels and biochemicals. Fast pyrolysis excels in handling a wide variety of feedstocks, making it adaptable to the diverse composition of landfill waste.

Fluidized Bed Pyrolysis:

Fluidized bed pyrolysis introduces a unique approach by suspending particles in a bed of hot, inert material. This method enhances heat transfer efficiency and allows for better control over the pyrolysis conditions. The fluidized bed technique is advantageous for processing finer and more heterogeneous waste materials commonly found in landfills.

Benefits of Pyrolysis for Landfill Waste:

Resource Recovery:

Pyrolysis extracts valuable resources from landfill waste, including biochar, bio-oil, and syngas. These products can be utilized in various industrial applications, offering a sustainable alternative to conventional fossil-based resources.

Reduced Greenhouse Gas Emissions:

By operating in an oxygen-deprived environment, pyrolysis minimizes the release of greenhouse gases compared to traditional incineration methods. This reduction in emissions contributes to mitigating climate change and environmental pollution.

Soil Improvement with Biochar:

Biochar, a by-product of pyrolysis, enhances soil fertility and structure. Its porous nature improves water retention and nutrient availability, making it a valuable soil amendment for agricultural purposes.

Bio-Oil for Renewable Energy:

The bio-oil produced through pyrolysis can be refined into renewable fuels, providing an alternative to fossil fuels. This contributes to the transition towards a more sustainable and low-carbon energy landscape.

Challenges and Solutions:

Feedstock Variability:

Landfill waste is inherently diverse, containing a mix of organic and inorganic materials. This variability poses a challenge for consistent pyrolysis processes. Advanced sorting and pre-processing techniques are being developed to address this issue, ensuring effective feedstock management.

Economic Viability:

The initial investment and operational costs of tdu thermal desorption unit can be significant. However, ongoing research and technological advancements are driving down costs and improving the overall economic viability of pyrolysis as a waste management solution.

Public Perception and Awareness:

Public perception and awareness of pyrolysis technology may impact its acceptance. Educational initiatives and transparent communication about the environmental benefits of pyrolysis are essential in overcoming these challenges and garnering public support.

Case Studies:

The Waste-to-Energy Plant:

Highlighting a successful implementation of pyrolysis technology in a waste-to-energy plant, showcasing how landfill waste is effectively transformed into valuable resources.

Community-Led Pyrolysis Initiatives:

Exploring grassroots efforts where communities are actively engaging in pyrolysis projects to address local landfill challenges and promote sustainable waste management practices.

Conclusion:

Pyrolysis innovations are at the forefront of transforming landfill waste from an environmental burden into a valuable resource. As technology continues to advance, the integration of pyrolysis into waste management practices holds the promise of a more sustainable and circular approach to handling our discarded materials. By harnessing the power of pyrolysis, we can pave the way for a greener, more efficient, and environmentally responsible future.