Introduction

Tyre pyrolysis, a cutting-edge technology, has gained prominence for its environmentally friendly approach towards tire waste management. This article delves into the intricate process of setting up a tyre pyrolysis plant project, ensuring a seamless and sustainable operation.

What is Tyre Pyrolysis?

Tyre pyrolysis is a thermochemical process that converts waste tires into valuable products like oil, carbon black, and steel. It involves the application of heat in the absence of oxygen to break down the rubber into its constituent components.

The Need for Tyre Pyrolysis Plant

With the increasing global concern over environmental issues, recycling and disposing of used tires responsibly has become a priority. The tyre pyrolysis plant plays a pivotal role in reducing the environmental impact of discarded tires.

Importance of Setting Up a Successful Project

To make a significant contribution to both environmental sustainability and profitability, establishing a well-planned tyre pyrolysis project is of paramount importance.

Preliminary Planning

Market Research and Feasibility Analysis

Conduct a comprehensive market research study to gauge the demand for pyrolysis products in your region. A feasibility analysis should assess the viability and potential obstacles of your project.

Regulatory Compliance and Permits

Ensure you have a thorough understanding of local, state, and federal regulations governing waste management and emissions. Acquire all necessary permits and approvals.

Location Selection and Site Preparation

The plant’s location is pivotal. Select a site that complies with zoning laws and provides adequate space for your operation. Prepare the site for equipment installation and ensure it’s accessible for transportation.

Equipment and Technology

Selecting the Right Pyrolysis Technology

Choose the most suitable pyrolysis technology based on the type of tires you plan to process and the desired end products. Factors to consider include batch vs. continuous processes and reactor types. They have different tyre pyrolysis plant cost.

Sourcing Essential Machinery and Components

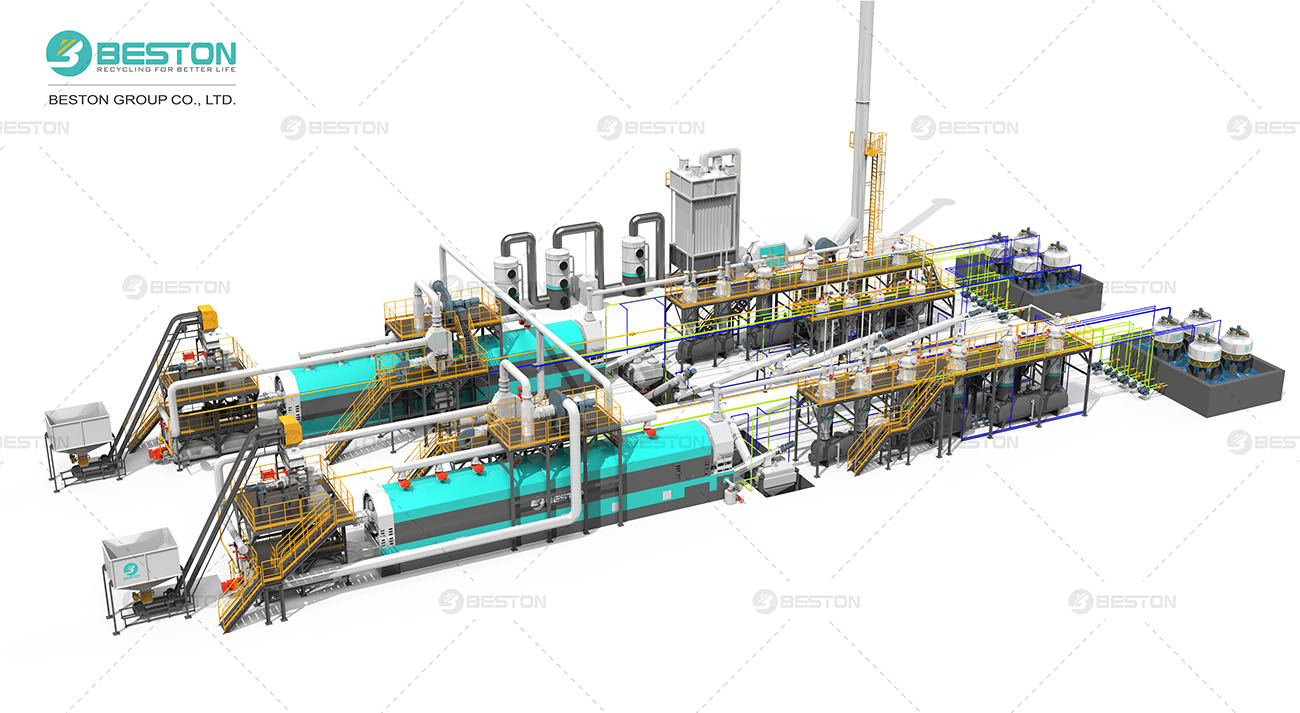

Procure the necessary equipment, including the reactor, condenser, and gas cleaning system. Quality is paramount here, so select reliable suppliers with a proven track record.

Ensuring Safety Measures

Prioritize safety by implementing proper ventilation, fire suppression systems, and employee training in handling hazardous materials.

Financial Considerations

Initial Investment and Budgeting

Calculate your initial investment, considering equipment costs, site preparation, permits, and operational expenses. Develop a comprehensive budget to track expenses.

Financing Options and Investment Sources

Explore financing options, such as loans, grants, or private investors. Identify potential sources of capital to fund your project effectively.

ROI and Profitability Projections

Project your return on investment (ROI) and profitability by analyzing market trends, pricing, and operational costs. Realistic projections are essential for financial planning of the pyrolysis plant for sale.

Environmental Impact and Sustainability

Emission Control and Waste Management

Implement emission control systems to minimize the release of pollutants. Develop a waste management strategy to handle the byproducts effectively.

Sustainability Practices in Tyre Pyrolysis

Consider sustainable practices, such as using solar or wind energy to power your plant and incorporating recycling methods within the facility.

Regulatory Compliance

Stay updated with changing environmental regulations and adapt your operations to ensure continuous compliance.

Operations and Maintenance

Staffing and Workforce Training

Employ qualified staff and provide training on safety protocols, machine operation, and emergency procedures.

Operational Protocols and Safety Procedures

Establish strict operational protocols, including safety procedures, maintenance schedules, and waste handling guidelines.

Routine Maintenance and Quality Control

Regularly maintain your equipment to ensure efficient and safe operation. Implement quality control measures to guarantee product consistency and customer satisfaction.

In conclusion, setting up a tyre pyrolysis plant project is a complex but rewarding endeavor. By carefully following the outlined steps and addressing each aspect meticulously, you can contribute to environmental sustainability while building a profitable business in the growing field of tire recycling. If you want get more information about a tyre pyrolysis plant project, you’re welcome to consult Beston Group Co., Ltd., an experienced pyrolysis plant manufacturer.