A tire pyrolysis plant is a revolutionary solution in waste management and resource recovery. This advanced technology allows for the conversion of used tires into valuable products such as pyrolysis oil, carbon black, and steel wire. The significance of tire pyrolysis lies in its ability to address the growing problem of tire waste while offering a profitable and sustainable business opportunity.

When considering an investment in a tire pyrolysis plant, conducting a comprehensive cost analysis becomes imperative. This article delves into the various factors that influence the overall cost of a tire pyrolysis plant and highlights the importance of understanding these elements before making a financial commitment.

Factors Affecting Tire Pyrolysis Plant Cost

- Plant capacity and scale: Understanding the impact of size on costs

The size and capacity of a tire pyrolysis plant play a crucial role in determining tyre pyrolysis plant cost. Larger plants generally require a higher investment due to the need for more land, equipment, and resources. However, they also offer the advantage of higher production volumes and economies of scale, which can lead to increased profitability in the long run.

- Technology and equipment selection: Exploring different options and their cost implications

The choice of technology and equipment for a tire pyrolysis plant significantly affects its cost. Advanced technologies may have a higher upfront investment but can offer enhanced efficiency, increased product yield, and improved environmental performance. Evaluating different options and considering their long-term benefits is essential in making an informed decision.

- Quality of materials: Evaluating the importance of durable and high-quality components

Using high-quality materials and components in the construction of a tire pyrolysis plant ensures its durability, reliability, and longevity. While opting for superior materials may come at a slightly higher cost initially, it reduces the risk of frequent breakdowns, maintenance expenses, and production interruptions in the future.

- Automation and control systems: Examining the benefits and costs of advanced systems

Incorporating automation and advanced control systems in a continuous tyre pyrolysis plant can streamline operations, improve process efficiency, and reduce labor requirements. While the initial investment in automation technology may be higher, the long-term benefits in terms of increased productivity, minimized human error, and improved safety can lead to substantial cost savings.

Cost Breakdown of a Tire Pyrolysis Plant

- Initial investment costs: Land preparation, equipment purchase, installation, and commissioning

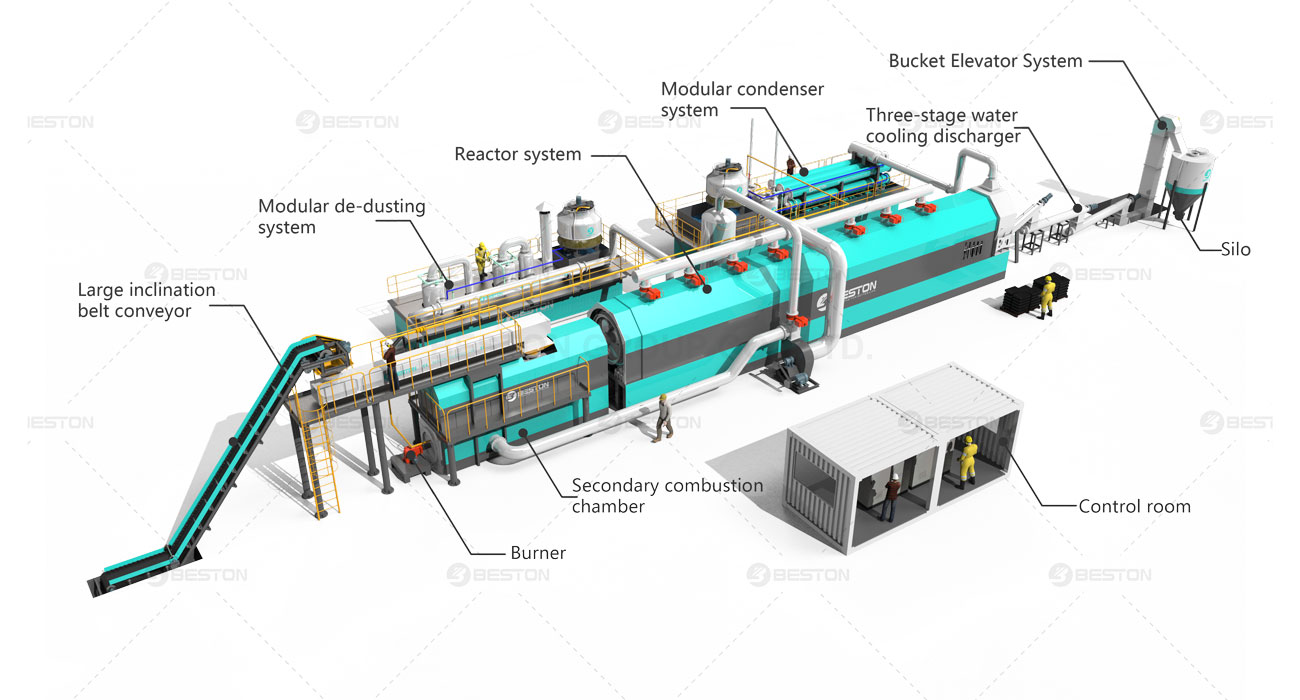

The initial investment costs of a tire pyrolysis plant include acquiring suitable land for the facility, purchasing the necessary equipment such as reactors, condensers, and distillation systems, and covering expenses related to installation and commissioning. It is essential to factor in these costs accurately to determine the total investment required.

- Operational costs: Raw material acquisition, energy consumption, labor, and maintenance expenses

Operating a tire pyrolysis plant involves ongoing expenses such as procuring raw materials (used tires), energy consumption for heating processes, labor wages, and regular maintenance costs. Properly estimating these operational costs is crucial for establishing a sustainable and profitable operation.

Analyzing Return on Investment (ROI)

- Revenue streams: Exploring potential income from pyrolysis oil and by-products

The primary revenue stream of a tire pyrolysis plant is the sale of pyrolysis oil, which can be used as a substitute for conventional fossil fuels. Additionally, valuable by-products like carbon black and steel wire can be sold for various applications. Understanding the market demand for these products and their potential pricing is vital in assessing the revenue potential of the plant.

- Market demand and pricing: Understanding market dynamics and their impact on profitability

The profitability of a tyre to oil plant depends on the market demand and pricing of the end products. Factors such as the availability of alternative fuel sources, environmental regulations, and the overall market landscape can influence the selling price of pyrolysis oil and by-products. Analyzing market dynamics helps in formulating a realistic revenue projection.

- Cost recovery period: Assessing the time required to recoup the initial investment

Determining the cost recovery period is a crucial aspect of any investment. By considering the revenue generated, operational costs, and the initial investment, it becomes possible to estimate the time required to recover the capital and start generating profits. This analysis aids in evaluating the financial feasibility and potential return on investment of the tire pyrolysis plant.

Evaluating Operational Efficiency

- Plant productivity and throughput: Maximizing production capacity and efficiency

Maximizing plant productivity and throughput directly impact the profitability of a tire pyrolysis plant. Efficient handling of feedstock, optimized processing parameters, and well-maintained equipment ensure smooth operations and increased output. Implementing best practices and continuous process improvement strategies contribute to enhancing overall efficiency.

- Yield and quality of end products: Ensuring high-quality output and maximizing value

The yield and quality of the end products, such as pyrolysis oil, carbon black, and steel wire, significantly influence the profitability of a tire pyrolysis plant. Efficient pyrolysis processes, proper waste segregation, and effective refining techniques are essential in obtaining high-quality products with maximum market value.

- Energy efficiency and waste management: Implementing strategies to optimize energy consumption and minimize waste

Efficient energy utilization and waste management practices are vital for sustainable and cost-effective operations. Employing energy-saving technologies, utilizing waste heat recovery systems, and implementing effective waste disposal methods contribute to reducing operational costs and environmental impact.

Conclusion

In conclusion, conducting a thorough tire pyrolysis plant cost analysis is imperative for investors seeking to capitalize on this innovative waste management solution. By considering factors such as plant capacity, technology selection, quality of materials, automation, and control systems, one can make informed decisions about the initial investment. Another important factor is a reliable manufacturer. Here I recommend Beston Group to you, a supplier with excellent technology, service, and experience.

A comprehensive breakdown of costs, including initial investment and operational expenses, allows for realistic financial planning and evaluation of profitability. Analyzing revenue streams, market demand, and pricing provides insights into the potential return on investment, while evaluating operational efficiency ensures optimal productivity and sustainable operations.

By exploring the hidden savings and understanding the intricacies of tire pyrolysis plant cost analysis, investors can embark on a path that contributes to waste reduction and unlocks lucrative business opportunities in the circular economy.