The conversion of tyres into burnable fuel has been a process used by many people over the decades. It is done through pyrolysis, a chemical process, which uses heat as a catalyst for this procedure. Tyres are made of components that will break down into charcoal, as well as bio oil and a type of biofuel similar to diesel fuel. This is why many people have invested into small waste tyre pyrolysis plants, and large pyrolysis plants, especially if they have access to millions of tyres. Whether you own a municipal solid waste plant where tyres are coming in every day, or if you are responsible for a tyre landfill, these can be very helpful. These are the benefits of having one or more of these machines at your disposal when converting tyres into burnable fuels. Besides, if you wanna get a reasonable pyrolysis plant cost, contact Beston directly.

Is This Process Simple Or Complex?

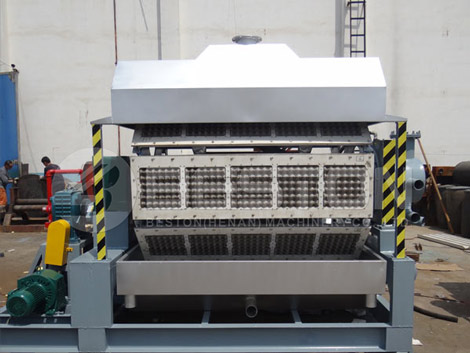

This is a very simple process that only uses heat as its main focal points of interest. The heat is increased in the pyrolysis chamber, and this causes the rubber to begin to change. Once the process is over, there will be liquid materials and solid materials. The solid material is charcoal. The liquid material is either a type of oil or a type of fuel that can be burned. Therefore, the vertical pyrolysis plant makes the entire process easy because all of the technical work has already been completed. Your job is to simply choose one that is efficient and easy to use, and is also affordable.

How To Obtain Good Waste Tyre Pyrolysis Plants

You can obtain one of these very easily by going to an advertising website that is constantly showcasing industrial equipment. Eventually, you will find several businesses that are offering these, many of which will be at an affordable price point. You must consider the process capabilities, and you should also consider the initial cost of the machines or plants. By considering how much you can sell the biochar and fuel for, you can determine how long it will take to pay off. Additionally, setting up accounts with different businesses ahead of time is highly recommended. You must have someone to sell the fuel produced through the pyrolysis process, and once you do, you will be ready to start selling what you produce from the waste tyres that go through this process.

Other Machines You May Need

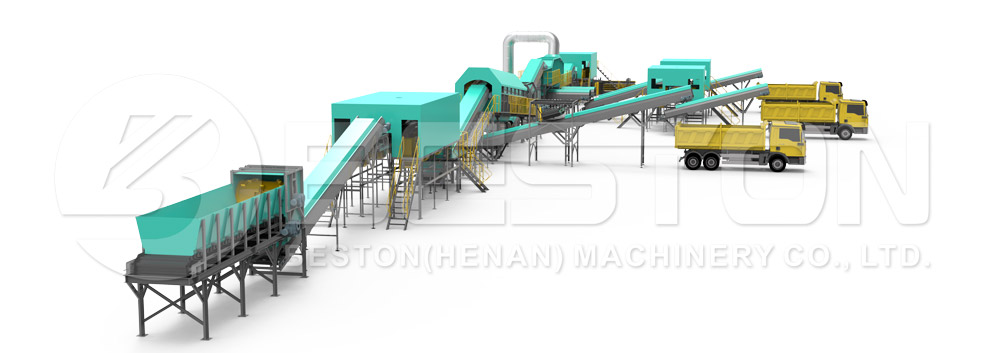

There are several other machines you may need to make this work. This includes a chipping machines that can break down the tyres into smaller pieces. The reason for the smaller pieces is so that the process of pyrolysis can be much more efficient. You also need a conveyor belt, storage bins, and likely one or two workers that can manage everything.

The conversion of rubber tyres into fuel could be a beneficial part of your business if you use the waste tyre pyrolysis plants. If your access to rubber tyres is quite large, perhaps receiving thousands of day, you certainly want to have one of these set up. If you are responsible for reducing the amount of rubber tyres in a landfill, this can also be very helpful. Send an email on this web: Beston Technology. Eventually, you will have a pyrolysis machine that can convert your waste tyres into fuel that will operate on a daily basis.