If you are planning to buy a tyre recycling plant, you might be wondering about the cost of buying a pyrolysis plant. The pyrolysis plant is available in a variety of configurations depending on capacity, type of technology used, type of materials used for making the plant, the components you want in your plant as well as the company manufacturing the plant among others. There is also the question of buying a semi-continuous plant or a fully continuous pyrolysis plant.

All these different configurations or types have their own advantages and their own price points. Therefore, the tyre recycling plant cost will depend on the type of recycling plant you want to buy for your unique requirements. Here is a list of the important parameters that will affect the final cost of pyrolysis plant:

Configuration

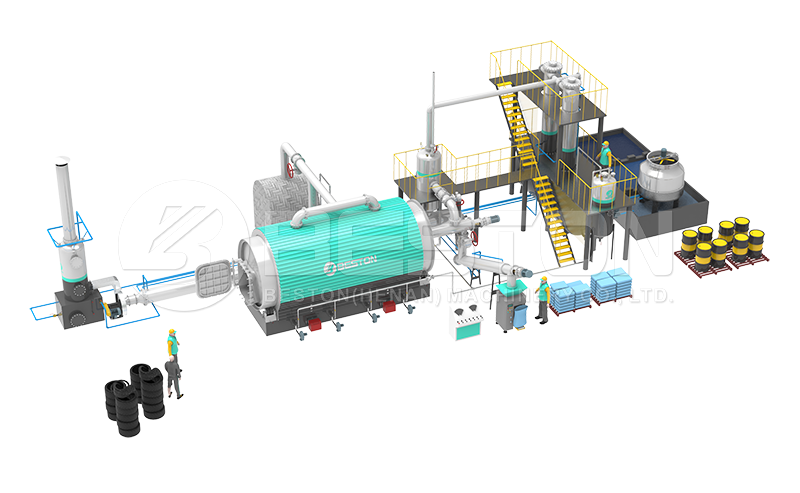

Firstly, you need to understand various components of a pyrolysis plant. Before you put waste tyres in the pyrolysis furnace, the waste tyres need to be cut down into smaller pieces in order to make it easier to process. This cutting is done in a tyre shredder machine. A tyre shredder is also a big investment. If you do not want to invest in a shredder, you would want to tie up with a company that already has the machine for shredding tyres into smaller pieces.

Another important difference between different types of recycling plants is the level of automation. In a semiautomatic plant, most of the processes require manual labor. For example, labor will be needed to feed the raw material into the pyrolysis chamber. Similarly, manual intervention would be required to get the finished products out of the pyrolysis chamber among other things. However, you also get to save you a lot of money in terms of initial cost of buying the plant. In the case of an automatic plant, there are conveyor belts or other systems that feed the raw material into the chamber and also get the finished products out of the chamber in an automatic fashion.

Efficiency

The pyrolysis technology has existed for many decades but manufacturers have added a lot of new tools in modern plants to enhance their overall efficiency. One major difference between old pyrolysis plants and modern plants is the level of efficiency. In case of modern plants, the heat generated in the pyrolysis process is rerouted to be used as fuel for the pyrolysis chamber. The modern plants cost a bit more but the enhanced efficiency of the overall process will pay for that small cost difference in no time. More models can be found: https://wasterecyclingplant.com/waste-tyre-pyrolysis-plant-for-sale/.

Pollution Control

In the pyrolysis process or tyre recycling process, a lot of pollutants or contaminants are generated. Modern environmental regulations require these pollutants to be captured and disposed of in an environmentally friendly manner. You will need to check the local regulations to understand what kind of pollution control needs to be installed in your plant. Thankfully, most modern tyre recycling plants come equipped with components that capture all the pollution causing gases to ensure compliance with the latest environmental regulations. Considering these factors, the tyre pyrolysis plant in India is asked to upgrade, more details can be found: https://wasterecyclingplant.com/batch-to-continuous-pyrolysis-plant/.

Conclusion

To conclude, the overall price of tyre recycling plant depends on a number of factors. Therefore, it is important for you to first define your business plan and lay down your requirements in terms of budget, labor availability and environmental regulations in order to buy a plant that is right for your particular location. Follow the above-mentioned tips to prepare your business plan and to choose the right tyre recycling plant.