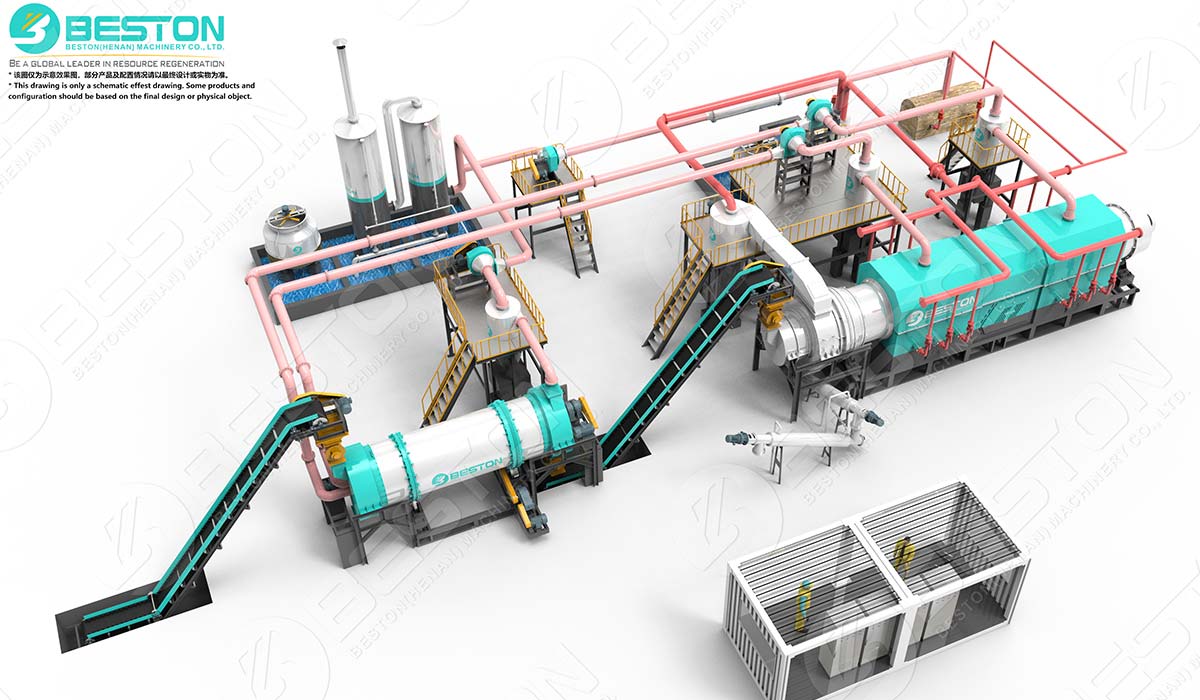

Are you interested in starting your own business? If you’re interested in starting your own business, and you don’t have a problem with the availability of rice husk and other biomass material, you should seriously consider investing in a machine that can convert biomass into charcoal. Several such machines are available at affordable prices. Here are important parameters that should allow you to buy a good quality rice husk carbonized machine(máquina de carbonización montado sobre patines) at the right price:

Input Capacity

As the name implies, it refers to the quantity of raw material that can be processed at a time in the machine. You can buy machines with input capacity as low as 10 cubic meters to more than 5 tons per hour. In short, there is a wide range of processing capacity, and you can choose one as per your specific needs.

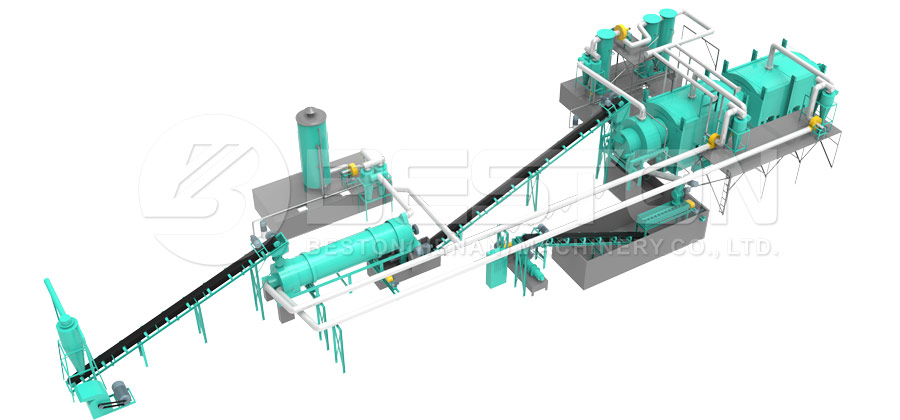

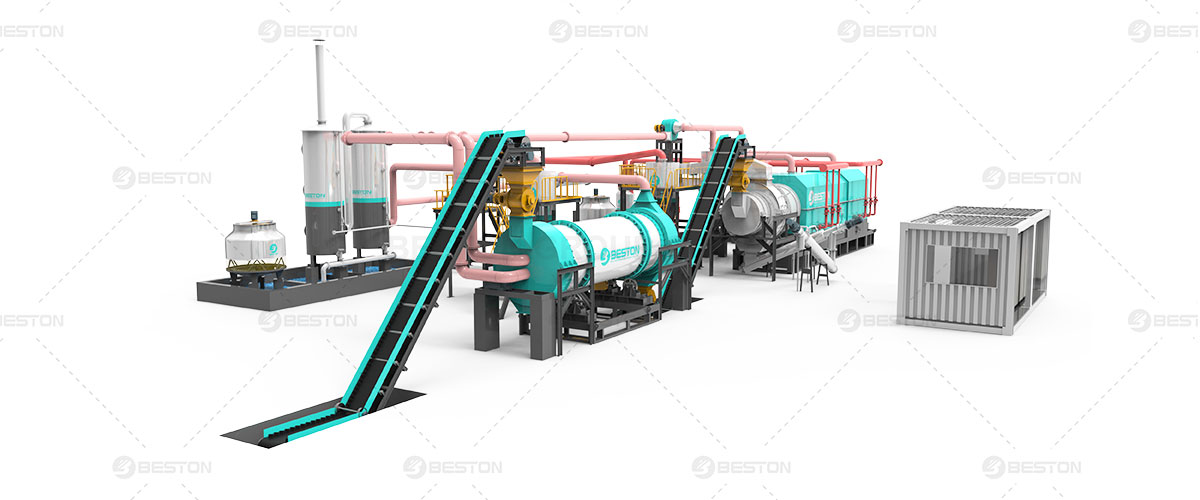

Configuration

These machines are available in batch type configuration as well as continuous design. Both these configurations have their own advantages. One big advantage of the continuous design is extremely high processing capacity, as these machines can operate 24 x 7 for several weeks. On the other hand, a batch type configuration has to be reloaded after a batch is finished and this is why, their processing capacity isn’t as high as a machine with continuous configuration.

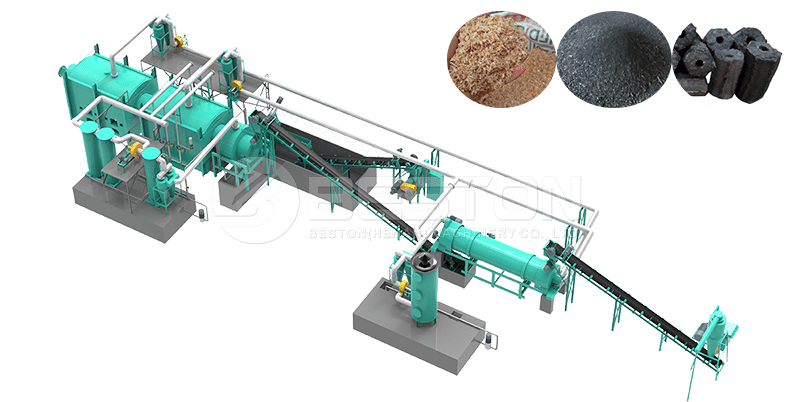

Types of Raw Materials That Can Be Processed

Most of these machines(máquina de reciclaje de Beston) are capable of processing a variety of biomass waste including coconut shells, sawdust and other materials in addition to rice husk. Some of these machines are also capable of processing municipal sludge, civil sludge as well as municipal solid waste. You should find out whether the machine you’re considering is capable of processing materials other than rice husk.

Possible Yield

The design plays an important role in the maximum yield that can be obtained from this machine. The yield mentioned by the manufacturers is typically measured under standard conditions but the real world conditions are always different. This is why you should get in touch with existing customers using these machines to find more about the real yield that can be obtained with the processing of different types of raw materials.

Fuel Type and Fuel Consumption

Find out about the type of heating materials that can be used in the machine(https://www.bestoneco.com/hornos-metalicos-para-hacer-carbon/). Some advanced designs are capable of using a wide range of materials including LPG, natural gas, diesel as well as biomass. Also pay attention to the energy consumption for processing of one batch. Needless to say, you would want to buy a machine with the highest fuel efficiency.

After Sales Service

Regular maintenance and servicing are necessary to enhance the operational life of this machine as well as keep it operating at optimum efficiency. You will also need replacement parts sometimes. This is why after sales service is extremely important. Buy it from a vendor that offers after sales service and is not just interested in making a sale.

Final Thoughts

Overall, there are several benefits of investing in a rice husk carbonized machine(maquina para hacer carbon vegetal). This machine can process a wide range of biomass, and there is a good demand for high-quality charcoal in a variety of industries. It is important that you compare the possible yield, type of raw materials that can be processed in the machine, and after sales service to buy the right machine.