Are you searching for a fully continuous tyre pyrolysis plant? Are you aware of the different types of these plants? Are you aware of the advantages of a continuous type plant? In this article, we will explore the biggest advantages of a continuous pyrolysis plant and how is it different from a batch type plant. We will also look at when it makes sense to buy a fully continuous tyre pyrolysis plant.

Pyrolysis plants are sold in various configurations but all these plants can be broadly categorized into two main types including continuous type plant and batch type plant. The major difference between these two types is that in a batch type plant, the processing takes place in batches. On the other hand, in a continuous type plant, the processing takes place continuously.

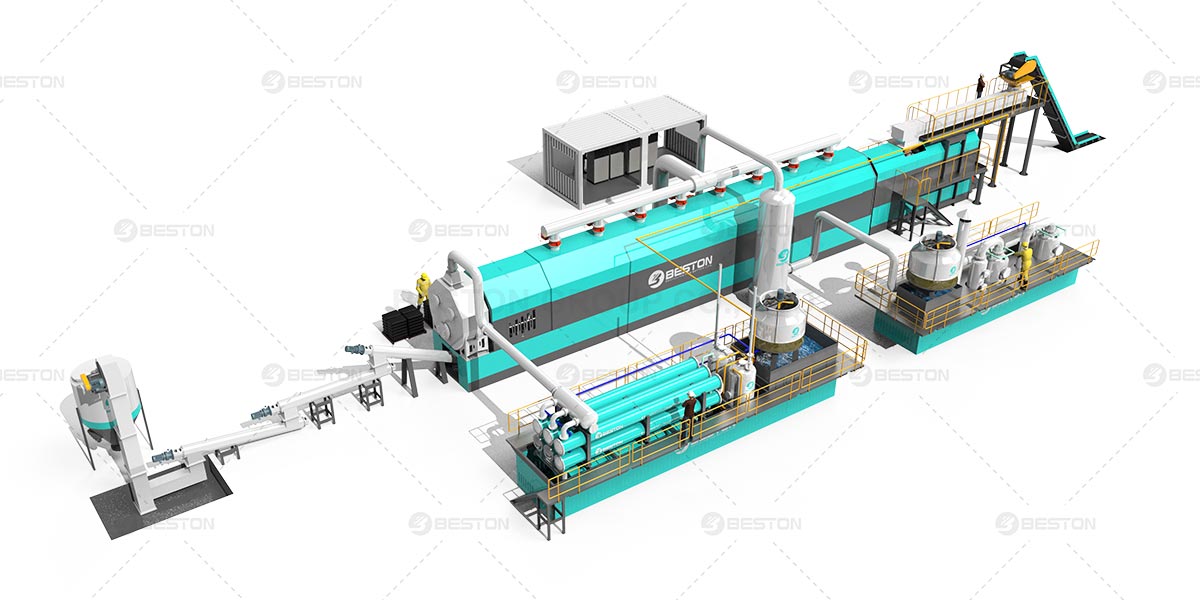

In short, the continuous scrap tyre pyrolysis plant can be operated 24 x 7, for several weeks at a stretch. You only need to ensure a consistent supply of raw material and the pyrolysis chamber will keep converting it into various products obtained from the process.

A big advantage of a continuous type scrap tyre pyrolysis plant is that it has a very high processing capacity, especially as it is able to process the raw materials continuously without requiring a break. It also has a simpler design as compared to the batch type plant which makes it easier to operate as well as maintain. However, it also has certain limitations as you don’t get as much flexibility with a continuous type plant as you get with a batch type plant. It makes sense to invest in a fully continuous type plant where you have a lot of raw material that can be continuously fed into the chamber for conversion.

The plants that have been designed in the 70s or 80s used to be good for their time but things have advanced a lot over the past few years. These days, you can easily get plants that produce considerably better yields as compared to the older plants. This is why it is always recommended to choose plants with modern designs in order to obtain a better yield.

Pyrolysis is also a power-hungry process which means you need to burn quite a bit of fuel in order to properly process waste tyres or any other materials. Designs with poor fuel efficiency lead to high operational costs and that cut in to your margins. This is why, you should always pay attention to the fuel efficiency of a pyrolysis plant in addition to its design, processing capacity, its type, its warranty, the reputation of the manufacturer, and other such things in order to get the best value for your money.

Overall, there are several advantages of investing in a fully continuous tyre pyrolysis plant. It has a much higher processing capacity and is capable of processing materials 24 x 7. Modern designs provide a far better yield as compared to older designs. This is why it makes sense to invest in a continuous type pyrolysis plant over a batch type waste tyre to oil plant when you have a lot of waste tyres to process.