You can track down the best charcoal making machine price before you spend anything. It’s good to get an idea of what you’re going to be able to do to get the best machine for the lowest price. Here, you will learn how to do that so be sure to continue reading.

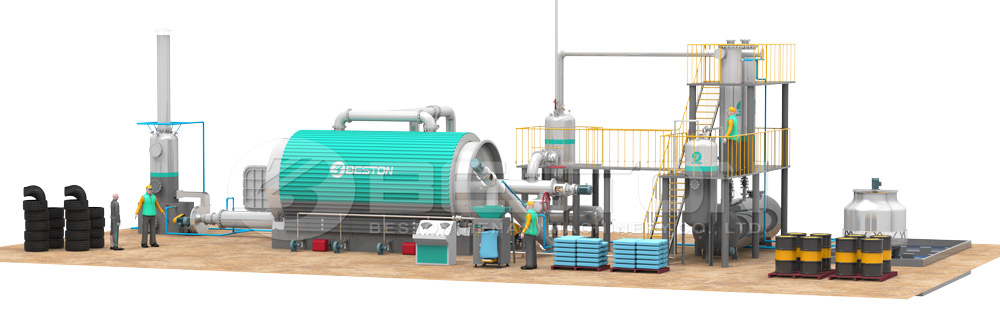

Take a look at reviews that are about the machine that you’re thinking of spending your money on. If a lot of people have only good things to say, then you will know that the machine is most likely a good fit. But, when many people tell you to avoid something at all costs, that’s something you need to listen to as well so you don’t end up getting stuck with something you’re sure to dislike. Try to read a handful of reviews and it should become clear whether something is going to be worth investing in or not. Check the charcoal making machine price here.

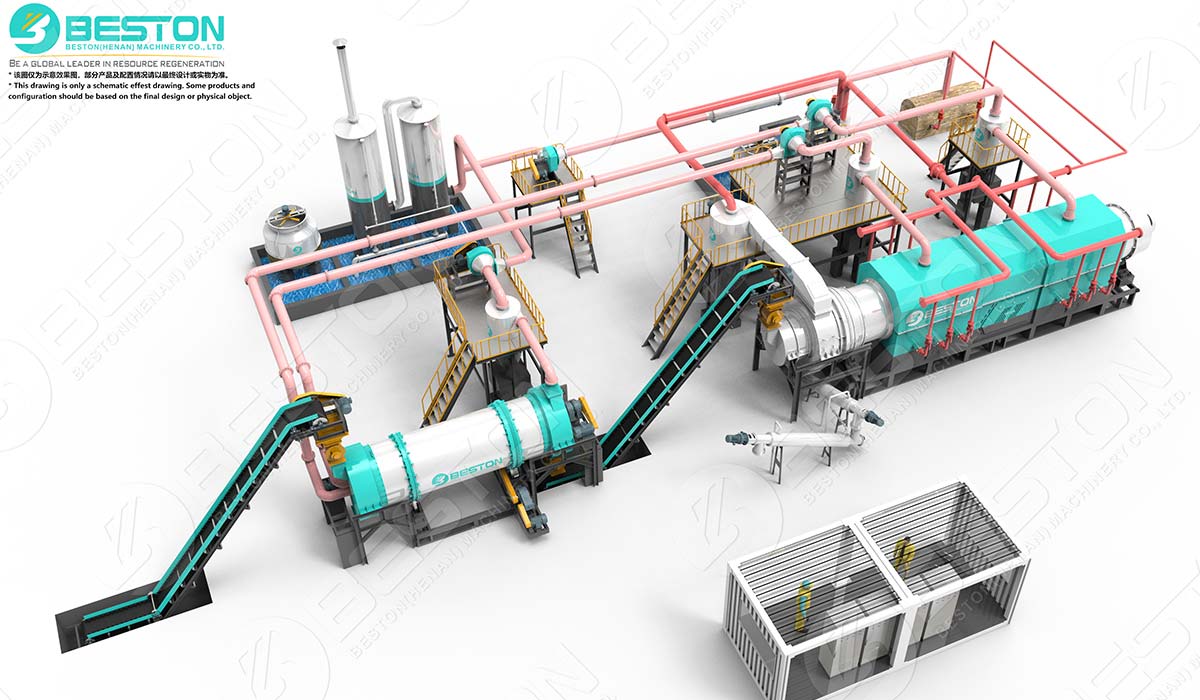

Do you know a lot about how to run the charcoal making machine? It’s important to take a look at what you need to do because instructions are going to help you run something without you having any big problems. You should try not to just figure it out as you go along because when you’re not sure about what to do, you can make mistakes that end in the biochar machine having quite a few issues. If you can’t find a guide on what to do online, try emailing the seller to see if they have anything they can share with you.

Find out what you’re able to do if you’re not happy with what you get when you buy a biochar production equipment. There are going to be problems sometimes, so you’re going to need to be able to send the machine back to the seller for a refund or a replacement if you run into issues. Some companies won’t work with you even if the problem is not your fault so you have to be aware of what your options are in the way of returns before you decide on which company to go through.

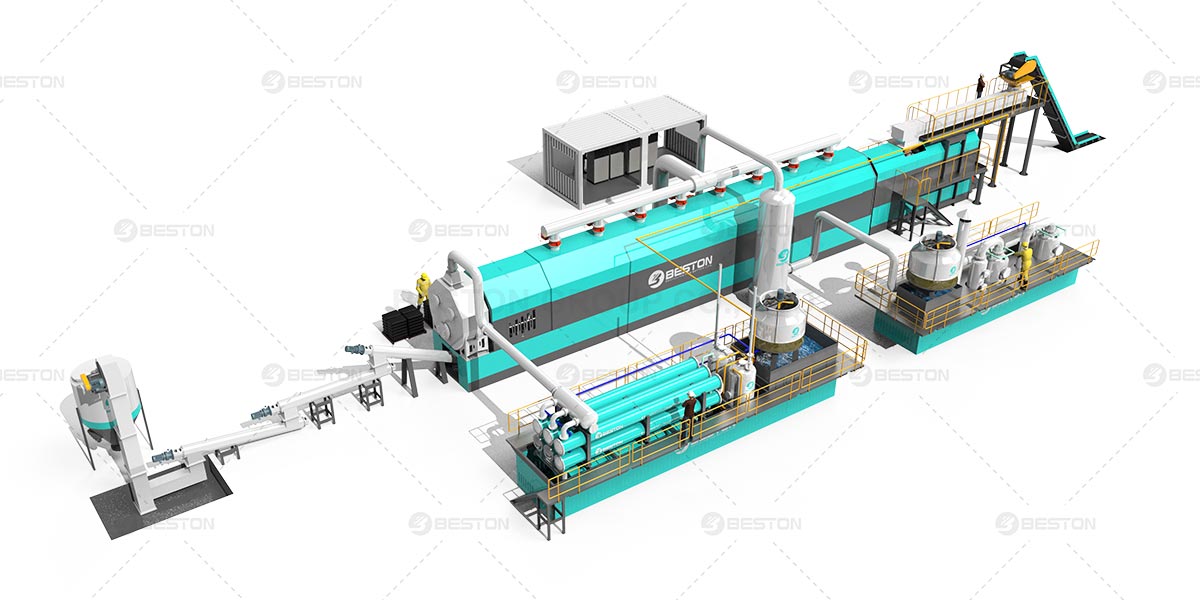

The right charcoal making machine price to pay is the one that is the most fair. You want to get as much as possible out of something for the lowest price. Take time to use what you learned here and you should be able to be happy with what you get. Get a sawdust charcoal making machine here.