You don’t have to buy charcoal from the store because you can start making it at home. Many people don’t know about the process of making charcoal and keep spending a lot buying from the shops. You will most likely be surprised when you find out how easy this process is. The raw materials used when making charcoal are cheap and even free at times. Instead of spending a lot of money on waste disposal, you can use the waste to make charcoal. You are going to save a lot of money in the process.

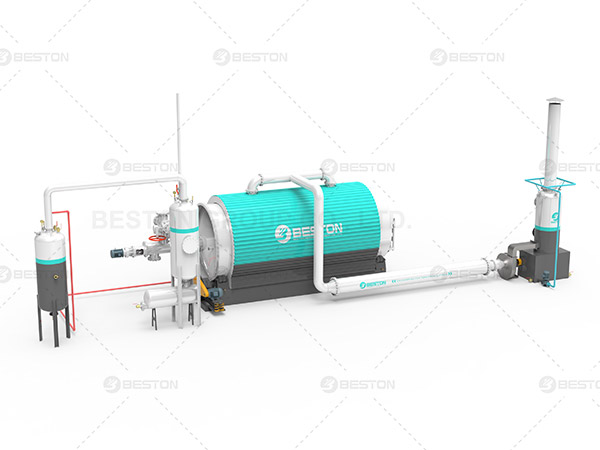

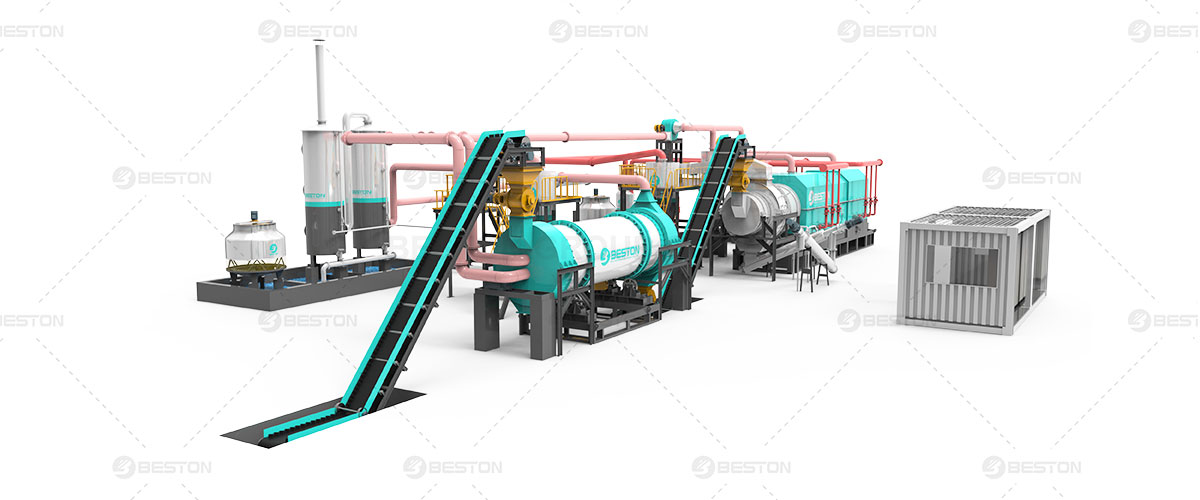

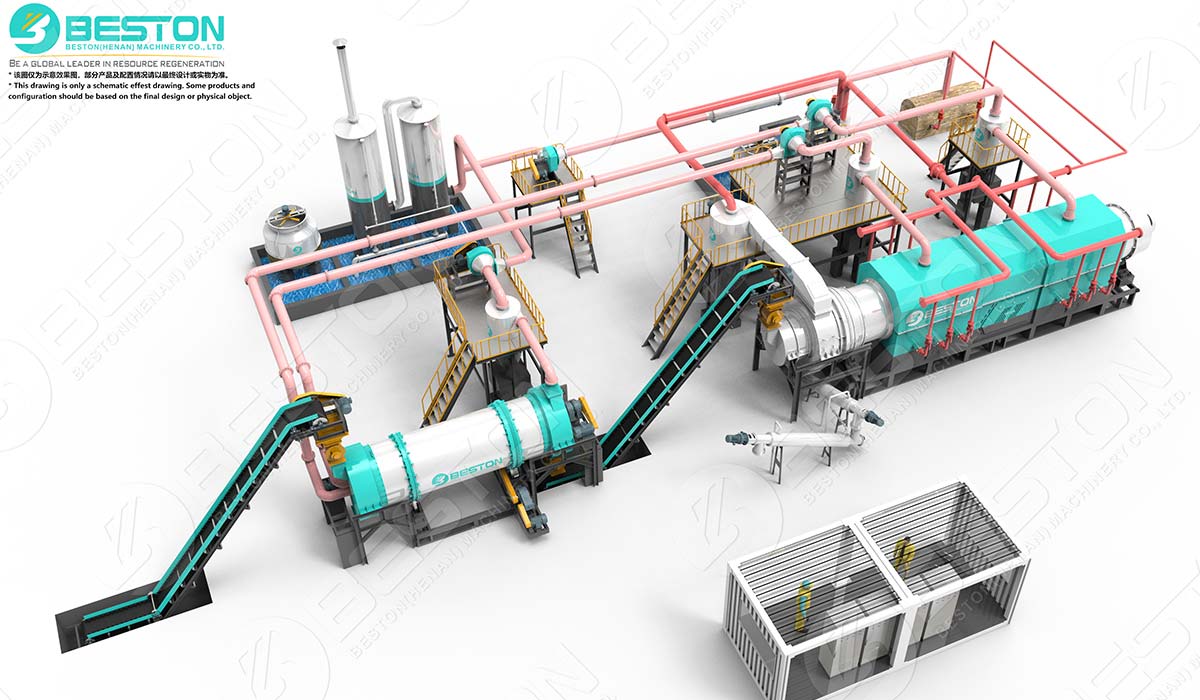

One thing that many people fear when it comes to making charcoal is the cost of the small charcoal making machine. You don’t have to worry because there is no need to spend a lot on industrial machines. Charcoal-making machines come in a wide range of sizes. You will find one that produces charcoal for your home. These are cheaper and you can easily operate the entire thing by yourself. It also doesn’t take a lot of time to make charcoal when you have the machine running properly. What are the benefits of buying a small charcoal-making machine?

Saves Money

You are going to save money because you no longer have to buy charcoal. If you produce more charcoal than you need, you can easily start selling the extra and make more money. This can be a new passive income that helps you cover some of your expenses. The machine is going to pay for itself in no time. You need to do a lot of research when buying a charcoal-making machine because you want one that works for you and also isn’t too big. A common mistake some make is buying a big machine hoping they will get a lot of orders for their charcoal. Start with a small one and then buy another when you need to upgrade. View the portable biochar kiln.

Cheap raw materials

You don’t have to cut down trees for you to make charcoal. You can use raw materials around you. The most common raw materials are rice husks, sawdust, wood scraps, and coconut shells. You can find these raw materials for free and sell the charcoal at a good price. This increases your profit margins. You don’t have to spend a lot on raw materials and you can easily find them around you. You can even find people giving you these waste products for free because it usually costs money to dispose of them.

Good for the environment

You will feel better using the machine because you are helping the environment. This helps the environment because the charcoal is coming from waste products and not trees that have been cut down for this specific purpose. Charcoal has a bad reputation because many people know that it is encouraging deforestation. You can use this charcoal without feeling guilty. Using recycled materials to make charcoal means fewer trees have to be cut down.

A small charcoal-making machine is an investment that is going to give a good ROI and you can use it at home. View this continuous type https://bestonmachinery.com/charcoal-making-machine/continuous/.