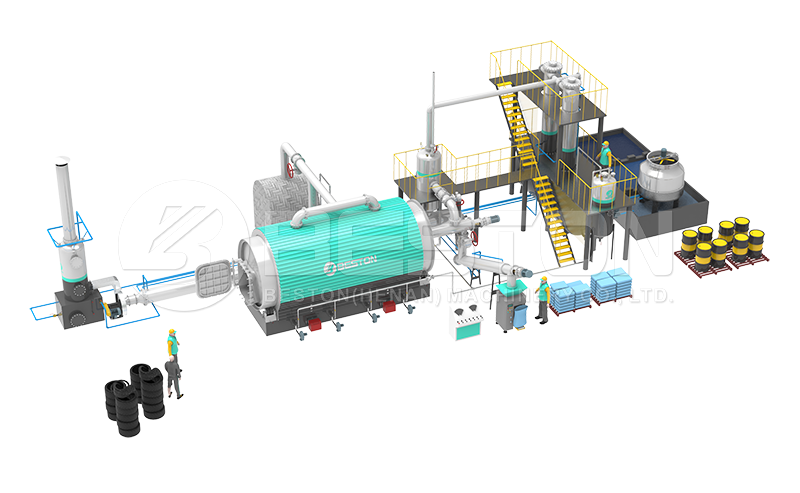

The tyre to oil plant is an essential piece of equipment that is used to obtain fuel oil from tyres and rubber products. The process through which oil is derived from tyres is known as pyrolysis, and it is a critical process because it helps in protecting the environment from pollution and degradation. The tyre pyrolysis plant cost is an essential aspect to consider when planning to commission the recycling plant. Several suppliers in the market deal with tyre recycling plants. Understanding what to consider before buying a tyre recycling plant can save someone months and years of regrets. Beston tyre pyrolysis plant is a plant that has several outstanding advantages that keep it leaps ahead of its competitors.

Tyre to Oil Plant Cost Considerations

The following points explain in details the key factors that should be considered before ordering a tyre pyrolysis plant.

1. Size of Recycling Site- The larger the size of the tyre recycling plant, the higher the setup cost. Plants that are expected to produce oil on large-scales require higher capital investments compared to small-scale plants which require smaller pieces of land.

2. Availability of Raw Materials- A tyre to oil plant that utilizes the readily available materials is more advantageous than a plant that utilizes raw materials that are not readily available. It is therefore critical to select a plant that will recycle raw materials that are easily accessible in your area.

3. Model of the Recycling Plant- The costs of the pyrolysis plants differ depending on the model and design of the plant. If you are looking for tyre recycling plant for sale, please contact Beston Machinery, which has various models for sale.

4. Cost of Pre-Treatment Machines- Besides the pyrolysis plant, other associated machines are purchased with it. The tyre shredder, for example, is an essential piece of equipment that should be commissioned with the tyre pyrolysis plant. The cost of such equipment will influence the overall cost of the tyre oil pyrolysis plant.

5. Local Costs- These are costs that have to be incurred to sustain production using the tyre pyrolysis plant. They include water bills, electricity bills, and registration bills. These costs should be considered too when planning to commission the plant because they have an impact on the profit margins of the pyrolysis plant.

6. Installation, Repair, and Maintenance Costs– The above tyre to oil plant costs are vital to consider when purchasing a particular tyre recycling plant. Owing to the advanced systems that are integrated into the tyre pyrolysis plant, maintenance and repairs will be required periodically. These activities will cost you money and should be considered before purchasing a specific tyre recycling plant.

7. Demand of the End Products- The nature of the market in your area will also determine whether you are going to purchase a particular plant or not. The higher the quality of the recycling end products, the higher the market value of the products, which translates to higher returns. The above point can be critical when deciding whether a particular pyrolysis plant is worthy or not.

Why Is Beston Tyre to Oil Plant Cost Manageable

1. Energy-Saving Techniques- Beston tyre recycling plant has incorporated efficient, effective, and advanced systems that help reduce its overall cost making it the best choice. The energy-saving features reduce the energy cost significantly.

2. Minimization of the Running Fuel Cost- New heating structures have been adopted in the tyre to oil plants which significantly reduce the cost of production of the plants. The heating systems are efficient, and this helps to cut down the fuel costs of the plant.

3. Full-Automation of Pyrolysis System- The Beston plant has fully-automated systems that help in reducing the number of workers. A reduction in the number of workers translates to a reduction in the cost of production of the plant which increases the profit margin of the plant. On the other hand, automation increases the efficiency of the machine since it eliminates errors that occur because of human mistakes.

4. Affordable Installation and Maintenance Costs- Beston Group has highly-trained and qualified engineers who are proficient at installation and maintenance. The engineers do the maintenance activities at subsidized prices for people who purchase recycling plants from the Beston Company. For this reason, the installation and maintenance costs are significantly reduced.

In summary, the above factors greatly affect the tyre to oil plant cost. The size of the recycling plant, availability of raw materials, design on the pyrolysis plant, cost of pre-treatment machines, installation or maintenance costs, and the nature of the market of recycling products should all be put into consideration before purchasing a tyre to oil pyrolysis plant so that the best decision is made.