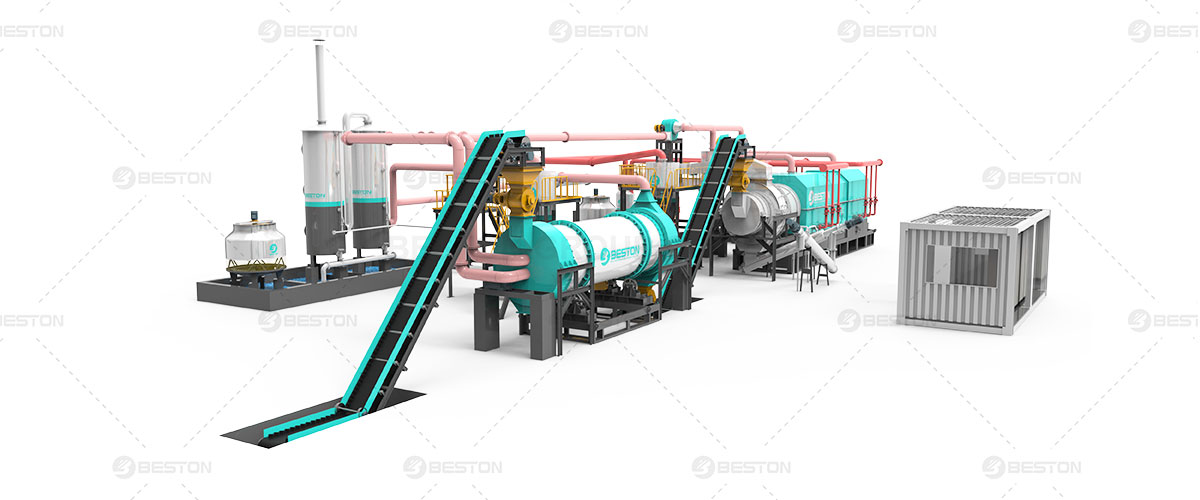

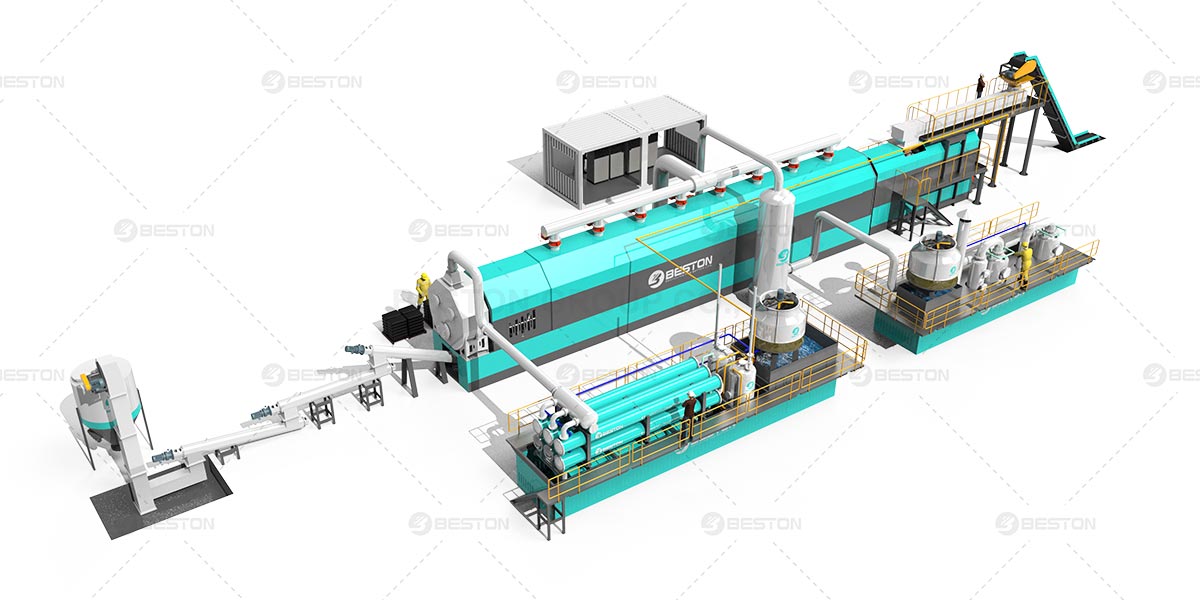

The sewage sludge carbonization machine takes sewage waste and turns it into high quality charcoal that you can sell for a great price. Sewage is a waste product that ends up in the landfills and is dangerous to have around, but this machine gets rid of the sewage and turns it into something you can use. The sewage sludge carbonization machine is affordable and it is easy to use which makes it a great investment in your business.

Sewage waste is a big problem because there is so much of it. It can quickly take over and cause so many problems to the environment. It’s important to have a way to remove this sludge and turn it into something you can use. This machine can process tons of sewage each hour and turn it into valuable charcoal.

Charcoal is a common ingredient in many products and it can also be used on its own too for cooking and heating purposes. It can also be used to make fertilizer. There are lots of uses for the charcoal and it is easy to sell since it is always in demand. Once you get the machine running you can start making money with it right away.

The charcoal making machine is easy to install and the manufacturer will actually install the machine for you and train your workers so everyone knows how to use it. They will ensure that everyone knows how to run the machine and they help you after the machine is installed as well. You get all of the aftersales service you need and they will help you with the machine for as long as you own it.

The biochar production equipment is very affordable and it comes in a few different models. The price of the machine depends on how large it is and what degree of automation you want with the machine. The automated machines are the most expensive and the manual machines are the most affordable. Think about how much charcoal you want to produce when you are shopping for the machines.

When you know how much charcoal you want to produce and how much waste you want to process with the machine. This machine makes it very easy to remove dangerous waste from the environment and it is a very eco-friendly option. The machine helps you get a lot done and it is so good for the environment.

When you start using this machine you will find that it is very affordable and that it produces lots of charcoal fast. The machine can easily be exported anywhere and the presales and aftersales service make it a great investment for your business. The charcoal is very easy to sell and you can make money with it.

The machine usually pays for itself fast and the cost is very affordable for what you get. You won’t need to hire a lot of people to run the machine and it gets rid of all of the sewage waste so it isn’t getting into the environment and causing problems. More information on Beston Group here.